¿Puede un engranaje de piñón y cremallera dañado provocar un tambaleo mortal?

In modern cars, the steering system is an important part of ensuring vehicle safety and stability. The steering system works together through multiple components to enable the driver to accurately control the direction of the vehicle. The rack and pinion gear are two critical components in the steering system, which are directly responsible for converting the driver's rotational input into the steering force of the wheels.

When these two components are damaged, it will not only affect the vehicle's handling, but is also likely to cause serious safety hazards. In particular, the phenomenon of "death wobble" usually refers to the sudden and violent swing of the vehicle's steering wheel, which makes the driver unable to control the direction, greatly increasing the risk of accidents.

This article will explore in depth whether a damaged rack and pinion gear will cause a "death wobble", and analyze the related causes, effects and countermeasures to help drivers understand how to avoid this potential danger.

What is the role of the rack and pinion gear?

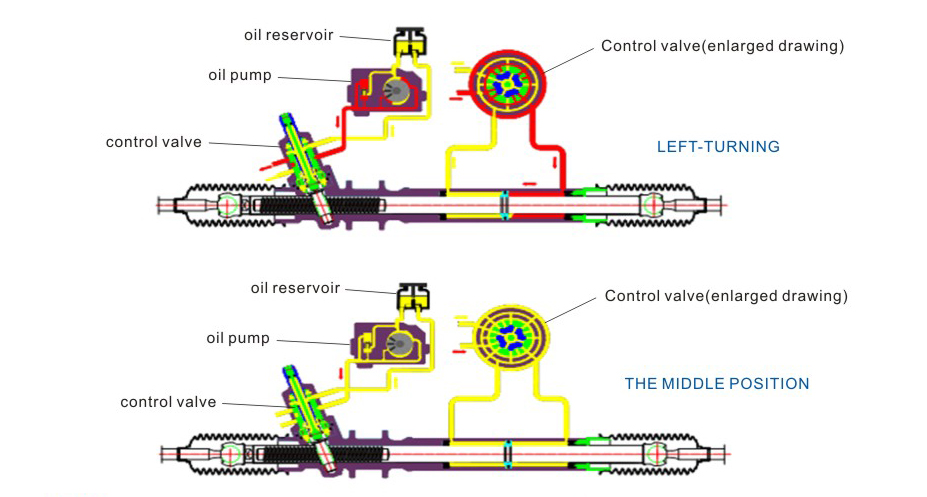

In traditional power steering systems, the rack and pinion gear play a vital role. In short, the rack and pinion gear work together at the core of the steering system, allowing the driver to easily control the direction of the vehicle. To better understand the potential risks of rack and pinion gear damage, let's first look at how they work:

·Rack: The rack is a linear, toothed metal strip that is usually connected to the steering rack. The rack and pinion work by meshing to convert the angle of the steering wheel into the steering action of the wheel. In the hydraulic power steering system, the role of the rack cannot be ignored. It provides the necessary power support for steering.

·Pinion: The pinion is a key component connecting the steering shaft and the rack. Its function is to transfer the rotational force applied by the driver through the steering wheel to the rack, so that the wheel turns in the desired direction.

These two components cooperate with each other to achieve precise steering function. And the precision of this cooperation also determines that their damage will directly affect the steering performance of the vehicle.

What are the causes of rack and pinion gear damage?

There are many reasons for rack and pinion gear damage, including material fatigue, wear, poor lubrication, external impact, manufacturing defects, etc. Specifically, the following situations are the most common:

·Excessive wear: During long-term use, the contact surface between the rack and pinion gear will gradually wear, resulting in poor meshing and affecting steering accuracy. Especially in the case of frequent driving, the wear problem will be aggravated, and in severe cases, it will cause the parts to loosen or fall off.

·Poor lubrication: The steering system needs to be regularly filled with lubricating oil to reduce friction and wear. If the lubricating oil is aged, contaminated or not replaced in time, the surface of the rack and pinion gear will lack the necessary lubrication, increase friction, and cause excessive wear or even jamming.

·External impact: Collisions, scratches or other external impacts may cause damage to steering system components, especially pinions and racks. These impacts may cause structural damage or deformation of components, thus affecting normal operation.

·Corrosion: The hydraulic oil used in hydraulic power steering systems may react with moisture, causing corrosion of internal parts. Corrosion not only affects the surface smoothness of rack and pinion gear, but also further aggravates wear and makes the system lose its original working ability.

·Manufacturing defects: Substandard parts or installation errors may also cause damage to rack and pinion gear. Manufacturing defects may cause inaccurate meshing between rack and pinion, thus affecting steering accuracy.

How does rack and pinion gear damage trigger "death wobble"?

"Death wobble" refers to the phenomenon that the vehicle's steering wheel suddenly swings violently and the driver cannot control it. This phenomenon usually occurs when the vehicle is driving at high speed, especially on highways or urban expressways, and may cause serious traffic accidents. Damage to the rack and pinion gear is one of the potential factors leading to this problem.

1. Poor meshing: Damage to the rack and pinion gear usually leads to poor meshing between the two. Wear, corrosion or deformation on the gear surface will increase the meshing clearance, resulting in the inability of the rack and pinion gear to match accurately. This poor meshing may cause the steering wheel to react erratically or even cause the steering wheel to suddenly deviate from the driver's control, resulting in the phenomenon of "death wobble".

2. Looseness or detachment: Loose or detached connection of the rack and pinion gear can cause steering to lose control. Especially in extreme driving situations, loose components can make the steering wheel feedback inaccurate or even completely lose control, causing the steering wheel to swing violently. This situation may cause the vehicle to deviate from the driving track and increase the risk of accidents.

3. Hydraulic system failure: If the oil in the hydraulic steering system cannot flow properly or the hydraulic oil leaks, the rotation of the rack and pinion gear may be hindered, causing the steering wheel to turn unsmoothly. When there is a problem with the hydraulic oil, the system may suddenly lose power, causing the driver to need more force to control the steering wheel, increasing the possibility of the vehicle's "death swing".

4. System vibration: Debido a la inestabilidad estructural causada por daños en el engranaje de piñón y cremallera, el vehículo puede experimentar vibraciones en el sistema de dirección, especialmente al conducir a altas velocidades. Estas vibraciones pueden verse amplificadas. La vibración no solo afecta el control del conductor, sino que también puede causar oscilaciones violentas del volante, lo que puede provocar accidentes.

5. Fallo del sistema de dirección:En los casos más graves, los daños en el engranaje de piñón y cremallera pueden provocar la falla total del sistema de dirección. Si el conductor no controla el volante, el vehículo pierde el control de la dirección, lo que impide una respuesta oportuna y aumenta considerablemente el riesgo de accidentes.

Cómo evitar que los daños en el engranaje de cremallera y piñón provoquen un tambaleo mortal

Para evitar que los daños en el engranaje de cremallera y piñón provoquen un tambaleo mortal, los propietarios de automóviles pueden tomar las siguientes medidas:

1. Revise periódicamente el sistema de dirección

Revise regularmente el estado del sistema de dirección, incluyendo el desgaste del piñón y la cremallera. Si la superficie del piñón o la cremallera está desgastada, corroída o deformada, repárela o reemplácela a tiempo. Las inspecciones regulares también deben incluir el sistema hidráulico para asegurar que el nivel de aceite hidráulico sea suficiente y que no haya fugas, a fin de evitar fallas hidráulicas.

2. Mantener una buena lubricación

Asegúrese de que el aceite lubricante del sistema de dirección esté en buen estado. El aceite lubricante puede reducir la fricción, retrasar el desgaste del engranaje de cremallera y piñón, y evitar que se dañe por falta de lubricación. Revise la calidad del aceite regularmente y reemplácelo según las recomendaciones del fabricante.

3. Evite el uso excesivo del volante

Girar el volante excesivamente o hacer virajes bruscos puede aumentar el desgaste del piñón y la cremallera y el riesgo de daños. El conductor debe evitar girar el volante excesivamente, especialmente al estacionar o conducir a baja velocidad.

4. Reparar rápidamente las piezas dañadas

Inspeccione y repare el engranaje de cremallera lo antes posible si detecta problemas como ruidos inusuales en el sistema de dirección, volantes pesados o dirección inestable. Evite retrasar las reparaciones para evitar daños mayores y la pérdida del control de la dirección.

5. Asegúrese de que las piezas estén instaladas correctamente

Una instalación incorrecta o piezas de baja calidad aumentarán el riesgo de daños.engranaje de cremallera y piñónAl reemplazar piezas, elija piezas originales y asegúrese de que la mano de obra de instalación cumpla con los estándares.

Soluciones de dirección de bajo coste de DKM

En Guangdong Diamond Auto Parts Co., Ltd. (DKM), ofrecemos soluciones asequibles de dirección asistida para fabricantes y concesionarios de automóviles. Desde nuestra fundación en 1996, nos hemos consolidado como una empresa reconocida por la fabricación de productos de alta calidad a precios competitivos.

Nuestra fábrica en Foshan, China, utiliza tecnología avanzada para fabricar cajas de dirección para marcas populares como Toyota, Honda y Mitsubishi. Ya sea que necesite sistemas de caja de dirección personalizados o opciones de compra al por mayor, ofrecemos precios bajos y soluciones flexibles.